Senior Design at LETU

Engineering Senior Design Projects and the elite lab experiences that accompany them are a cornerstone of hands-on industry preparation at The Christian Polytechnic University. We are a community of builders.

At LeTourneau University, we implement engineering design and project-based learning throughout our entire curriculum. During the senior year, engineering students participate in a year-long capstone project as part of a multi-disciplinary teams. LETU students complete a wide variety of projects that involve collegiate competition, applied research, industry skills and humanitarian service. These team projects embody the learn-by-doing philosophy for which LETU is known.

Check out our 2025-2026 Senior Design Projects:

3D Metal Printing - Wire Arc Additive Manufacturing (WAAM) with Ferrous Alloys and Materials Testing (Dr. Dai)

Additive manufacturing (AM) or 3D printing is a very popular technology in contemporary industry and academia. As one of the major metal 3D printing methods, wire arc additive manufacturing (WAAM) can build customized parts with relatively complex geometry and relatively large dimensions due to high material deposition rate. As the welding engineering lab at LeTourneau University has brought in one industry welding robot and one welding cobot, we saw the potential for LeTourneau University to develop the WAAM capability, to catch up the state-of-the-art of modern manufacturing technology and reflect our identity as the Christian Polytechnic University. This senior design team will develop capability of WAAM on the Yaskawa industry welding robot and/or the Yaskawa welding cobot. They will also study the influence of welding parameters on microstructure and mechanical properties of the additive manufactured wall of stainless steels. Finally, parts with complicated geometry will be made using the newly developed WAAM capability.

Additive manufacturing (AM) or 3D printing is a very popular technology in contemporary industry and academia. As one of the major metal 3D printing methods, wire arc additive manufacturing (WAAM) can build customized parts with relatively complex geometry and relatively large dimensions due to high material deposition rate. As the welding engineering lab at LeTourneau University has brought in one industry welding robot and one welding cobot, we saw the potential for LeTourneau University to develop the WAAM capability, to catch up the state-of-the-art of modern manufacturing technology and reflect our identity as the Christian Polytechnic University. This senior design team will develop capability of WAAM on the Yaskawa industry welding robot and/or the Yaskawa welding cobot. They will also study the influence of welding parameters on microstructure and mechanical properties of the additive manufactured wall of stainless steels. Finally, parts with complicated geometry will be made using the newly developed WAAM capability.

Airport Utilities and Aviation Maintenance Building Design (Dr. Jiang)

East Texas Regional Airport is planning to develop its vacant land to attract aviation-related businesses and support future airport expansion. Currently, the airport is evaluating the construction of a new airplane maintenance facility on a wooded parcel of land that lacks existing utility infrastructure. The senior design team will be tasked with designing a facility that will serve both an airplane maintenance company and the airport. The scope of the project includes Site Preparation Plan and Design, Utilities Plan and Design, Facility Design, Roadway Design, and MEP Systems Design (mechanical, electrical, and plumbing) to support the operational needs of the maintenance facility.

East Texas Regional Airport is planning to develop its vacant land to attract aviation-related businesses and support future airport expansion. Currently, the airport is evaluating the construction of a new airplane maintenance facility on a wooded parcel of land that lacks existing utility infrastructure. The senior design team will be tasked with designing a facility that will serve both an airplane maintenance company and the airport. The scope of the project includes Site Preparation Plan and Design, Utilities Plan and Design, Facility Design, Roadway Design, and MEP Systems Design (mechanical, electrical, and plumbing) to support the operational needs of the maintenance facility.

E-Gen: Project Electrogenesis (Dr. J. Kim)

This second year project is focused on advancing LeTourneau’s knowledge of semiconductor fabrication. The project goal is to design, prototype, and produce a maskless lithography machine that will enable in-house design of complex semiconductor patterns. Achieving this requires the integration of a precision motion gantry system, advanced optical control, custom backend software, and robust electronic hardware.

This second year project is focused on advancing LeTourneau’s knowledge of semiconductor fabrication. The project goal is to design, prototype, and produce a maskless lithography machine that will enable in-house design of complex semiconductor patterns. Achieving this requires the integration of a precision motion gantry system, advanced optical control, custom backend software, and robust electronic hardware.

FENNEC: Center of Gravity Estimation using Neural Networks for Rotary-Wing Aircraft (Dr. Davis)

In this project students will investigate the ability of machine learning methods to identify the center of gravity for a rotary-winged aircraft (helicopter UAS) using flight test data from commercially available controllers. Additional areas of research include evaluating the use of Neural Networks to distinguish between multiple operators flying the UAS and investigating the use of pre-trained Neural Networks for real-time fault detection. Teams will combine flight tests, experiment design, analytical methods, and machine leaning to answer the posed research questions. Project can accept only U.S. Citizens and U.S. Nationals. Students should be willing to travel to present to the client in April.

In this project students will investigate the ability of machine learning methods to identify the center of gravity for a rotary-winged aircraft (helicopter UAS) using flight test data from commercially available controllers. Additional areas of research include evaluating the use of Neural Networks to distinguish between multiple operators flying the UAS and investigating the use of pre-trained Neural Networks for real-time fault detection. Teams will combine flight tests, experiment design, analytical methods, and machine leaning to answer the posed research questions. Project can accept only U.S. Citizens and U.S. Nationals. Students should be willing to travel to present to the client in April.

Fluids Lab Overhaul (Prof. Tixier)

Knowledge and experience with instrumentation, data acquisition, and control systems is a desired skill for manufacturing and test engineer roles and related jobs in industry. Students will upgrade an existing lab device by investigating the instrumentation and data acquisition necessary to modernize it for an engineering lab and a fluid mechanics demonstration system for industry training. Similar efforts may also be applied to a refrigeration system. Focus is primarily on the instrumentation, testing, and analysis, using the fluids and refrigeration devices as a research and test bed.

Knowledge and experience with instrumentation, data acquisition, and control systems is a desired skill for manufacturing and test engineer roles and related jobs in industry. Students will upgrade an existing lab device by investigating the instrumentation and data acquisition necessary to modernize it for an engineering lab and a fluid mechanics demonstration system for industry training. Similar efforts may also be applied to a refrigeration system. Focus is primarily on the instrumentation, testing, and analysis, using the fluids and refrigeration devices as a research and test bed.

Lazy Rivers (Dr. Low)

This project seeks to advance the understanding of lazy river hydraulics and provide a design tool useful for engineers in the aquatics industry. This design tool will be developed and validated using laboratory experimentation as well as measurement and modeling of full-scale lazy rivers. While the primary client will be Aqueous Engineering (Tyler, Texas), the collected data and validated model will also be prepared for dissemination in journal papers and conference presentations.

This project seeks to advance the understanding of lazy river hydraulics and provide a design tool useful for engineers in the aquatics industry. This design tool will be developed and validated using laboratory experimentation as well as measurement and modeling of full-scale lazy rivers. While the primary client will be Aqueous Engineering (Tyler, Texas), the collected data and validated model will also be prepared for dissemination in journal papers and conference presentations.

LeTourneau Competitive Robotics (Prof. Reese)

The team will design and construct two robots using the VEX robotics system and compete in the Texas state competition in Houston against other colleges. The competition changes each year and is comprised of an autonomous and driver-controlled period. The senior design team will work with students from the LCR club as well. In addition, we will host two tournaments for high school and middle school students.

The team will design and construct two robots using the VEX robotics system and compete in the Texas state competition in Houston against other colleges. The competition changes each year and is comprised of an autonomous and driver-controlled period. The senior design team will work with students from the LCR club as well. In addition, we will host two tournaments for high school and middle school students.

LETREP25: LeTourneau Rehabilitation Engineering Project 2025 (Dr. Sasaki)

Neurological disorders such as stroke and spinal cord injury often cause spasticity and contracture in the arm muscles that lead to rigid elbow, wrist, and finger joints in a flexed position. This project aims to develop a rehabilitation device to alleviate the symptoms. The device will consist of an adjustable mechanical framework, a servo motor with transmission to elicit a quick stretch in the arm flexor muscles (by a quick extension of the elbow joint), a force transducer to measure the stretch response, and software to control the motor and to provide the feedback information of the stretch response to the patient in a rehabilitation protocol called the operant conditioning of spinal reflex. In addition to the device development, fundamental research will be conducted on whether the force information of stretch reflex can be reliably obtained, which aims at eventual academic dissemination (e.g., conference presentations).

Neurological disorders such as stroke and spinal cord injury often cause spasticity and contracture in the arm muscles that lead to rigid elbow, wrist, and finger joints in a flexed position. This project aims to develop a rehabilitation device to alleviate the symptoms. The device will consist of an adjustable mechanical framework, a servo motor with transmission to elicit a quick stretch in the arm flexor muscles (by a quick extension of the elbow joint), a force transducer to measure the stretch response, and software to control the motor and to provide the feedback information of the stretch response to the patient in a rehabilitation protocol called the operant conditioning of spinal reflex. In addition to the device development, fundamental research will be conducted on whether the force information of stretch reflex can be reliably obtained, which aims at eventual academic dissemination (e.g., conference presentations).

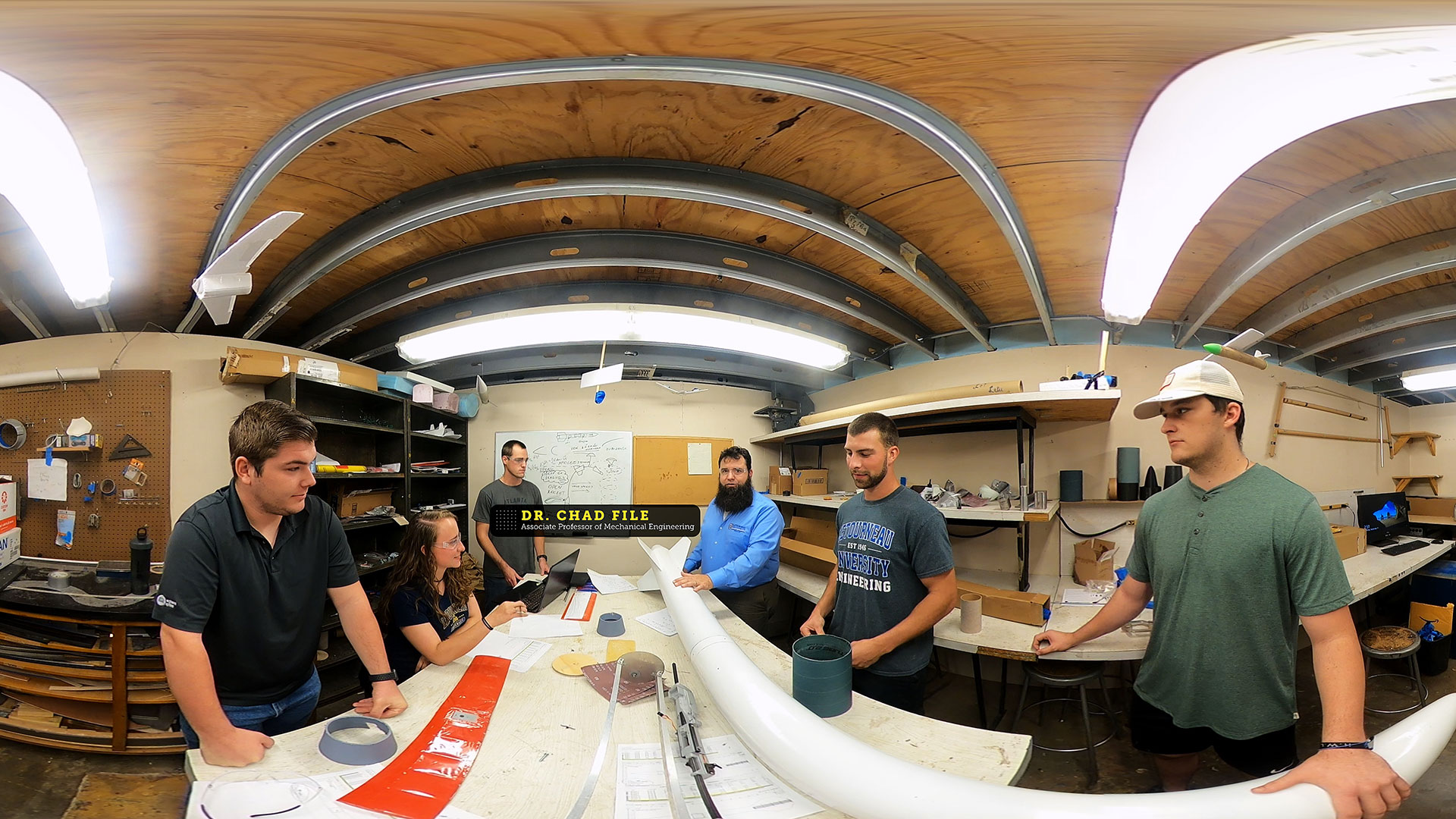

LUNAR: LeTourneau University Nexus for Amateur Rocketry (Dr. File)

The LUNAR rocket team will design, build, and test a high-powered rocket for a national, collegiate competition during the late Spring semester. The design will focus on four (4) aspects.

The LUNAR rocket team will design, build, and test a high-powered rocket for a national, collegiate competition during the late Spring semester. The design will focus on four (4) aspects.

- Rocket construction: This includes the aerodynamic geometry of the fuselage including nose cone and fin design, motor selection, recovery apparatus, tracking methods, etc.

- Payload: The students will design a payload component that meets the requirements of the competition.

- Motor construction: A subset of students will design a process for solid motor construction. This must include safety protocols for both construction and testing. Students will provide documentation on manufacturing processes, testing procedures, and characterization.

- The team will take their finished---i.e., successfully tested---rocket and payload delivery vehicle to test the design and build. The grade for this component will be based primarily on design and execution aspects, with only completion scores received for applying to the competition

ON-Par: Putting Aid Robot (Prof. Tixier)

Last year, students designed and built a prototypical device to assist golfers with their putting skills. Device is intended to capture and return both accurate and errant balls, measure and record accuracy of putts for a session and track progress over time. Additional customer desires include identifying the putting green speed and terrain and aiding golfers with directional compensation skills. The unfinished prototype does none of these well and there are lots of opportunities for improvement, including pursuing marketability and commercialization.

SAE Baja: Renegade Racing (Prof. Johnson)

Design, build, and test a single-seat four-wheel-drive off-road vehicle to compete at a Society of Automotive Engineering (SAE) competition. The primary goal is to redesign portions of the 24/25 vehicle and improve upon our competition results.

Design, build, and test a single-seat four-wheel-drive off-road vehicle to compete at a Society of Automotive Engineering (SAE) competition. The primary goal is to redesign portions of the 24/25 vehicle and improve upon our competition results.

VMP: Verson Motor Project (Dr. J. Kim)

Students will partner with MuZ Motion, a high-performance electric motor company, to design, test, and improve a newly-developed, patented, ultra-light, high-torque, and intelligent motor. This next-generation technology has the potential to disrupt multiple industries, including aerospace, aviation, robotics, automation, automotive, and biomedical engineering. Through hands-on work in materials research, performance testing, and design refinement, students will gain valuable experience in developing high-efficiency electric motors while contributing to a product poised to make a significant impact on the global market.

Students will partner with MuZ Motion, a high-performance electric motor company, to design, test, and improve a newly-developed, patented, ultra-light, high-torque, and intelligent motor. This next-generation technology has the potential to disrupt multiple industries, including aerospace, aviation, robotics, automation, automotive, and biomedical engineering. Through hands-on work in materials research, performance testing, and design refinement, students will gain valuable experience in developing high-efficiency electric motors while contributing to a product poised to make a significant impact on the global market.